What is Manhole Rehabilitation? Benefits, Applications & Process for Trenchless Rehab

June 29, 2022

Written By Matt Huston

What is manhole rehabilitation?

Manhole rehabilitation is the process of reinforcing and restoring an aging manhole after years of wear and tear to avoid full replacement. Rehabilitation is essential for manhole maintenance to revitalize existing structures and steer clear of disaster down the line.

Damaged manholes are susceptible to inflow and infiltration issues which stem from excess ground or stormwater seeping through cracks or holes in the manhole structure. Structural collapse is a worst-case scenario but highly possible if manhole maintenance is neglected.

Is manhole rehabilitation only for municipalities?

Manhole rehabilitation is a good option for municipalities as well as independent facilities with their own sewer infrastructure.

Much like municipal manholes, manholes in industrial facilities are vulnerable not only to inflow and infiltration, but also corrosive conditions. Facilities that work with chemicals and other harsh substances can benefit even more from manhole maintenance as chemical runoff rich with hydrogen sulfide (H2S) weakens the manhole structure.

Instead of uprooting business and disturbing day-to-day operations with an expensive excavation and full manhole replacement, trenchless rehabilitation methods are well-suited for facilities to minimize expenses while maximizing efficiency.

Benefits of Trenchless Manhole Rehabilitation vs. Replacement

Industrial facilities and municipalities alike can trust trenchless manhole rehabilitation methods to restore the integrity of their infrastructures. There are several reasons why manhole rehabilitation makes more business sense than manhole replacement.

Manhole Rehabilitation is Cost Effective

Trenchless rehabilitation increases cost savings because you avoid the initial digging and the extra expense of having to rebuild afterward. Saving in both regards is one of the key reasons why rehabilitation is a preferred solution for manhole maintenance.

Manhole Rehabilitation Leads to Less (Or No) Downtime

Trenchless rehabilitation allows municipalities and facilities to stay fully focused on business matters because there is no need to shut down operations to accommodate large construction equipment and gaping holes. With no digging involved, rehabilitation crews are typically able to complete projects within 10 to 12 hours, without interrupting daily operations.

Some Trenchless Solutions Have a Lifespan Equivalent to Full Replacement

There are many types of trenchless rehabilitation methods with varying lifespans. For the best outcome, look for a solution that is fully structural and has a lifespan in line with replacement. With less hassle and a lower expense to implement, it makes more sense to rely on manhole rehabilitation for lasting longevity.

As a leading provider of trenchless rehabilitation services in the US, HK Solutions Group works with customers to ensure manholes are structurally sound. Our team of manhole rehabilitation contractors offers a unique approach to provide the appropriate solution for each customer’s needs.

How do you fix a manhole?

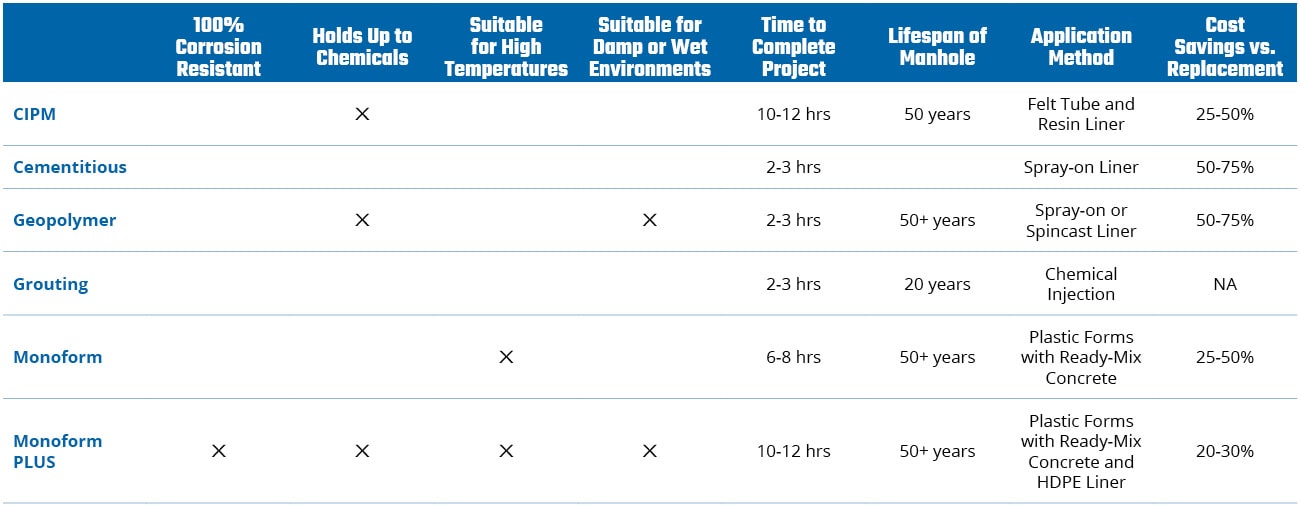

Since trenchless rehabilitation is so much more convenient and cost-effective than manhole replacement, there are a variety of manhole lining and grouting methods. Each has its own purpose depending on the status of your infrastructure.

Types of Manhole Rehabilitation

Cured in Place Manhole (CIPM)

A cured in place manhole (CIPM) liner is a felt tube that relies on resin in its core to tightly secure the manhole as the tube is inflated and the catyzed resin hardens. CIPM works well for traditional cylindrical manholes but typically requires larger crews and more equipment to get the job done than other trenchless rehabilitation methods.

Geopolymer Manhole Linings

Geopolymer linings are cement-based and act as a glue, coating the manhole and forming a seal to support the structure. HK Solutions Group is an industry leader in the application of geopolymer linings designed to combat corrosion. Geopolymer linings are effective in corrosive environments and provide a structural enhancement to the host structure.

Cementitious Liners

Cementitious liners are a relatively low-cost and easy-to-apply solution—typically cementitious manhole linings are applied during a low-pressure spraying process. They aren’t ideal for corrosive environments, but recent improvements have led to better protection against infiltration, lengthening the manhole’s lifespan.

Manhole Grouting with Chemical Injections

Manhole grouting is a good option for cracked or leaking structures and involves applying gel within the manhole to seal and waterproof the cracks and/or construction joints and seams to effectively prevent inflow and infiltration. Grouting is preferred for sealing manhole structures subject to leaking but is not recommended for infrastructures that are structurally failing, as a more comprehensive approach is required for advanced deterioration.

Monoform™ Manhole Rehabilitation Solutions

While HK Solutions Group offers solutions across the spectrum of available trenchless rehabilitation methods, we have found some projects require outside the box thinking. This is why our trademarked Monoform™ and Monoform Plus ™ manhole lining solutions innovative answers to the most challenging manhole issues. Whether sewer structures are located in a strenuous environment (such as areas of extreme heat or highly corrosive areas) or have simply deteriorated over time, one of our Monoform™ solutions will ensure the lasting integrity of your infrastructure. In fact, our Monoform™ solutions have the equivalent lifespan of a full manhole replacement without the unnecessary expense and interruption to your day-to-day operations.

Monoform™

Our original Monoform™ is a 100% structural solution enhancing sewer systems without the need for excavation. Experts from the HK Solutions Group team use plastic forms to mold high strength, fiber-reinforced ready mixed concrete around the manhole, with the form quickly and easily removed afterward.

Monoform PLUS™

Monoform PLUS™ combines the trusted Monoform™ solution with a high density polyethylene (HDPE) Agru corrosion protection barrier. These two technologies combine for a 100% structural and 100% corrosion resistant remedy in corrosive geographies or facilities working frequently with chemicals. HDPE manhole linings are durable and last longer than traditional manhole structures that deteriorate rapidly from high H2S concentrations.

The Monoform™ Process for Manhole Rehabilitation

With unparalleled longevity and success, Monoform™ and Monoform PLUS™ are HK Solutions Group’s preferred trenchless manhole rehabilitation methods.

To ensure we take the appropriate approach to best assist each of our customers, we start the process with a 3D manhole scan to pinpoint issues within the manhole and provide a detailed deficiency report.

Next, we are able to identify the best Monoform™ application and put a plan in place to get straight to work.

How long does it take to repair a manhole?

HK Solutions Group typically spends no more than 8 to 12 hours on-site per structure with minimal to no disruption to the day’s regular workflow. Once completed, the proven success of the Monoform™ solutions guarantees the complete restoration of your manhole infrastructure for many years to come.

Other available trenchless rehabilitation methods can take longer depending on the project and without the same guarantee of a full lifespan. HK Solutions Group and our many customers trust Monoform™ as the best manhole rehabilitation solution on the market.

Contact HK Solutions Group for Trenchless Manhole Rehabilitation Services

Our entire process is designed for your convenience to keep your city or business functioning properly. To learn more about our talented team of experts and top-of-the-line Monoform™ manhole rehabilitation solutions,

contact us online or call us at

(855) 845-5326 to get started.

Matt Huston

Matt’s expansive career spans 30 years working with trenchless, structural manhole rehabilitation technology to provide no-dig sewer solutions for industrial and municipal customers throughout the Midwest.

Over the years, Matt has been heavily involved with the Wisconsin Rural Water Association and Wisconsin Wastewater Operators’ Association, working his way through numerous committee positions to provide leadership to peers in the industry. He has also hosted impactful presentations for the associations outlining sewer system maintenance and structural manhole rehabilitation techniques.

Learn More About Matt