Avoid Silo Blockages with Routine Grain Bin & Silo Cleaning Services

December 4, 2023

Whether farming, food manufacturing, mining or maintaining other bulk storage materials, a smooth-flowing silo is critical to production, profit and safety. Silos are meant for safekeeping goods in bulk, often for materials that must be kept to food-grade quality but they can just as easily set production back if not properly maintained. Regular grain bin and silo cleaning are essential for routine maintenance to eliminate silo blockages, restore silo capacity and ensure materials are safely stored in a contamination-free environment.

Why do silos need to be cleaned?

Without consistent silo cleaning, businesses risk mold, insects and harmful bacteria contaminating stored goods. Silo blockages are also likely, slowing flow, limiting storage capacity and prohibiting optimal production. Silo cleaning clears out what would otherwise be wasted material, maximizing profits while minimizing losses.

Sticking to a silo maintenance and grain bin cleaning schedule is also a matter of safety. If you’re storing animal feed or food products intended for consumers, there’s the expectation that these items will be safe to eat. For materials that aren’t intended for consumption, blockages and slow flow can lessen the quality of the goods. No matter what materials you’re working with, failing to keep up with regular industrial silo cleaning endangers your business’ reputation and output if goods aren’t up to par.

Along with eliminating silo blockages and clearing the vessel to allow for its full capacity, regular silo maintenance makes business sense for the longevity of your industrial storage capabilities. Routine cleaning keeps silos in top condition longer, preventing the need for costly repairs and allowing silos to be in operation for decades. Being proactive with industrial silo cleaning is the best way to secure your critical storage vessels for long-term usage.

How often do silos need to be cleaned?

To keep stored goods from growing mold or deteriorating in quality, silos should be thoroughly cleaned every six months. However, industrial silo cleaning needs vary depending on the weather, what’s being stored and how frequently the silo is emptied. If you notice recurring silo blockages, opt for more regular maintenance to prevent buildups.

For example, a silo storing food-grade items in a humid, wet environment would likely need more regular maintenance than a silo with mining products in a consistently dry environment due to the risks of mold and bacteria growth. To find a silo cleaning schedule that works for your business, consider what, if any, risk factors are likely, including leaks, mold or residue buildups. You can prevent these problems from escalating by making routine silo cleaning and maintenance a more consistent part of your production schedule.

When in doubt, it’s always better to plan for silo maintenance instead of letting blockages build up, potentially causing an unplanned pause in production.

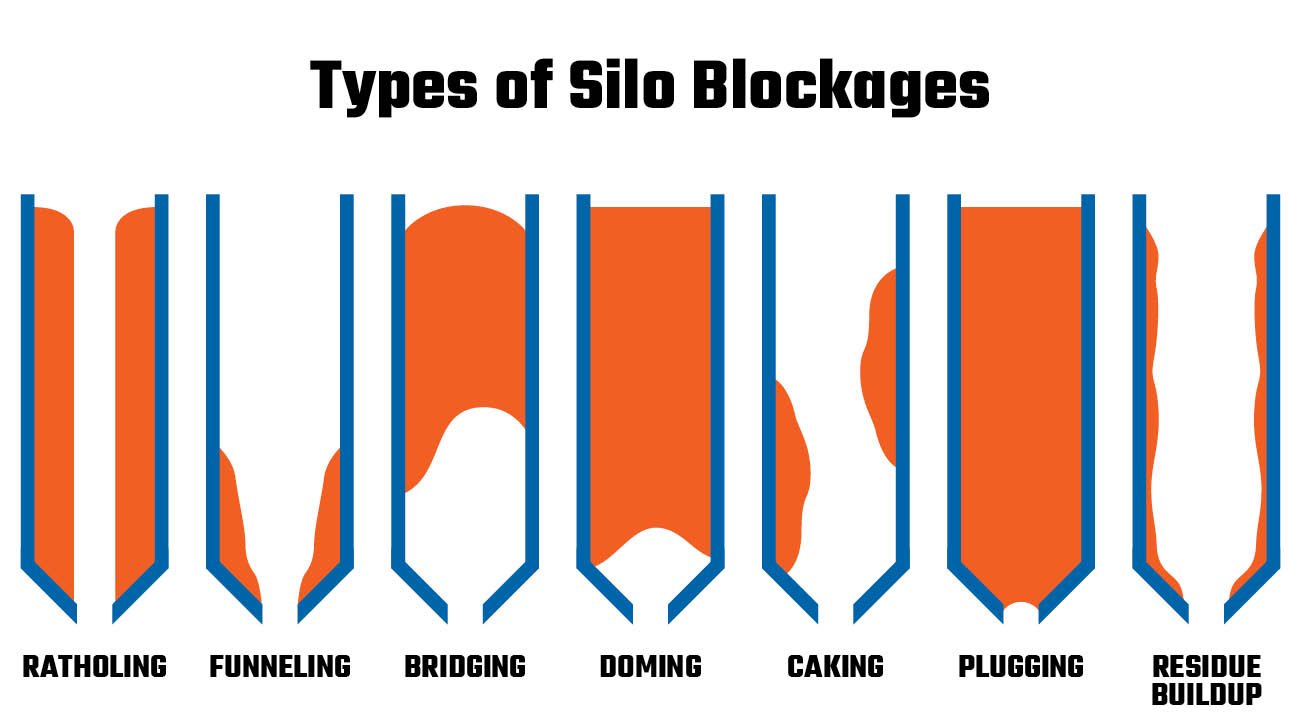

What are types of silo blockages?

Silo blockages take many forms, building off each other to grow in size and restrict flow. Common blockages include:

- Ratholes

- Funneling

- Bridges

- Doming

- Caking

- Plugging

- Residue buildups

Ratholes & Funneling

Ratholes and funneling blockages form a similar shape inside the silo. Both occur when stored goods cling to the side of the silo structure, leaving only a small hole for any remaining material to pass through in the center. This blockage lessens the silo capacity, limiting the flow of material and slowing production down. Meanwhile, the goods stuck to the silo walls are left stagnant, making the materials more susceptible to mold or bacterial growth. These silo blockages waste materials and harm your bottom line.

Bridges & Doming

Bridges and doming also share similarities. Both blockages are caused by materials binding together within the silo due to compression or interlocking particles. As the names suggest, bridges and doming form an arch-like shape, obstructing anything above the blockage from flowing through to the silo outlet. This not only prohibits flow but also adds pressure to the silo walls, increasing the risk of a structural failure and lessening the integrity of the vessel.

Caking & Plugging

Food items like livestock feed, flour and other powdery, granular materials are susceptible to caking, which creates silo blockages, essentially “plugging” the silo. Caking becomes an issue when materials are left dormant for too long or are exposed to moisture. The particles clump together and act as a plug preventing materials from passing through the silo. Caking is likely indicative of a larger issue or blockage within your silo because moisture and stagnation should typically be avoided.

Residue Buildups & More Silo Blockages

It’s not always obvious what types of silo blockages are present in your vessels, but all of them are harmful to production and potentially the stored products if left alone for too long. Even allowing residue to build up due to infrequent silo cleaning can trigger other types of blockages and set off a domino effect in your grain bins and storage vessels. Simply adding more material to the silo will not clear up the blockage. In fact, it will strengthen it and make it bigger. Instead, there are a variety of silo cleaning methods available to safely and efficiently remove the culprit.

Silo Cleaning Methods

Today’s industrial silo cleaning methods are designed with safety in mind, eliminating the need for confined space entry and preventing exposure to breathing or combustion hazards. Methods like industrial vacuums and hydroblasting meet this criteria, but hydraulic and pneumatic whips are the best solution to most effectively clear out silo blockages.

Industrial Vacuuming & Vacuum Trucks

Vacuums and vacuum truck services are safe silo cleaning methods to vacuum up residue and remove blockages, whether your facility stores liquid or granular materials. The vacuum, typically anchored to a specialty vacuum truck, is inserted into the silo to remove loose material. While personnel entry isn’t required to complete silo cleaning via vacuuming, results are limited by the vacuum’s capabilities. Vacuums are well-equipped to remove loose debris, but if a rathole or residue buildup is present, the suction likely won’t be able to remove the material clinging to the silo walls.

Industrial Hydroblasting

Industrial hydroblasting equipment is used to clean a variety of surfaces, structures and equipment. This silo cleaning method relies on a high-pressure, targeted water stream to blast away residue and debris within the vessel. No confined space entry is needed and no chemicals are involved. However, wet silo cleaning methods do introduce potential mold and other contamination due to moisture if not properly ventilated and dried out.

Silo Whipping Services

Pneumatic and hydraulic bin drills provide safe, cost-effective and efficient silo cleaning methods through the silo whipping technique. HK Solutions Group has more than 30 years of experience cleaning silos and performing other industrial services across the country, and our trusted, proven silo cleaning method is silo whipping. Whipping is effective for grain bin cleaning as well as maintenance for various other vessels.

HK has experience using both pneumatic and hydraulic bin drills, with the difference being pneumatic drills are powered through pressurized air, while hydraulic bin drills are powered using oil and water. We can help determine what equipment is most compatible with your silo cleaning needs but know both methods use careful precision to eliminate silo blockages.

To start, drills are inserted into the silo’s access hatch, where they begin using their powerful arms to loosen—i.e. whip—residue and blockages, restoring flow and storage capacity within the vessel. No confined space entry is required, and our equipment is designed for safe usage in various silo types and structures. This ensures no damage is done to the silo in the process and reduces the risk of hazards like sparking and combustion.

How to Choose a Qualified Industrial Silo Cleaning Services Provider

Top concerns for businesses seeking industrial silo cleaning services are safety, experience and cost-effectiveness. Questions to consider before hiring a silo maintenance team include:

- Is the team trained/experienced with multiple types of silos and storage materials? (e.g., grain bins, cement storage, feed, flour, food, liquid, etc.)

- What silo cleaning methods do they use? Do these methods carry any risks? Is confined space entry required?

- If confined space entry is required, does the team have the proper certifications, equipment and safety procedures?

- Are their safety procedures and techniques compliant with guidance from the Occupational Safety and Health Administration (OSHA) and other requirements in your state?

Evaluating a silo cleaning service provider based on these criteria will ensure you employ a team with the training, experience and care required to execute the job safely and affordably. HK Solutions Group has decades of experience performing silo maintenance and grain bin cleaning services for numerous industries and countless bulk storage applications.

While our team members do maintain confined space entry certification should it be required for a project, our preferred silo whipping solution means we rarely have to enter the tank and risks are minimized every step of the way. We are a trusted silo cleaning services company providing superior cleaning and more industrial services throughout the Midwest and beyond.

Call HK for Safe & Effective Silo Maintenance & Grain Bin Cleaning Today

For that check all of your boxes, consider HK Solutions Group your partner for the job. We work across a variety of industries providing trusted silo maintenance and grain bin cleaning solutions. Our team executes silo cleaning methods recognized for being the safest, most cost-effective solutions available. Call HK at 515-283-0500, or contact us today to see how we can help remove pesky silo blockages and boost your bottom line by restoring full capacity to your silo storage and flow.

Contact HK For Silo Cleaning Services