How To Prevent Inflow & Infiltration (I&I) Issues In Sewer Systems

November 6, 2025

Aging and deteriorating sewer structures and collections systems pose major risks and liability concerns for municipalities managing community infrastructure. Chief among these challenges is inflow and infiltration, also known as I&I, which occurs when excess groundwater and stormwater enter the sewer system. In turn, already over-burdened collections systems are forced beyond capacity, potentially causing discharge of untreated wastewater, residential sewer backups and flooding.

If left untreated, inflow and infiltration (I&I) can strain sanitary sewer treatment plants and lead to unplanned municipal expenses. Learn how manhole leaking makes your sewer system susceptible to groundwater infiltration and discover how manhole rehabilitation can help mitigate I&I. But first, be sure to know what you’re up against!

Understanding The Difference Between Infiltration & Inflow

Though inflow and infiltration often go hand-in-hand, they’re actually individual issues with their own unique causes. Infiltration occurs more gradually as groundwater enters the collections system through deteriorating infrastructure, like cracks in pipes, leaks in manhole gaskets and seals and failed pipe joints and lateral gaskets. It’s usually triggered by large storms or prolonged precipitation. Because the process is often prolonged and drawn out over a long period of time, strain to the sanitary system continues to escalate, driving costs up through inefficient operation and continued wear and tear.

Inflow, on the other hand, occurs rapidly as a result of heavy rainfall, snowfall or snow melt overpowering the collection system. Stormwater runoff and surface water enter the collection system through sump pumps and other pathways of least resistance including manhole covers, downspouts and chimney sections. This excess water quickly causes the system to exceed capacity, leading to sewer backups in homes and even the city streets. The main difference between infiltration and inflow is onset, but whether it’s the slow degradation of your sewer system over time or a rapid system failure from flooding or heavy rainfall, both I&I come with major consequences if ignored.

Why Manhole Leaking, Inflow & Infiltration Are A Problem For Municipalities

An overwhelming amount of inflow and groundwater infiltration in sewer systems has the potential to not only damage sewer structures and manholes but also residential properties as a result of sump pump backups. Any risk to municipal infrastructure also falls back on homeowners who are dependent on critical wastewater disposal and treatment utilities. In addition to the potential damage I&I causes, the strain on wastewater treatment facilities also inflates costs for municipalities and residents. Groundwater routed to and treated alongside wastewater at treatment facilities creates an unnecessary cost burden on wastewater plants and their customers.

If inflow and infiltration are not addressed, sanitary sewer pipes become unable to handle peak flow and need to be sized up. This type of pipeline project is extremely expensive and does not solve the root of the I&I problem. In fact, I&I are often indicative of underlying issues in your sewer system, which are better solved with cost-effective manhole rehabilitation solutions rather than a disruptive structural replacement.

When & How To Check For I&I

If sewer flows at your municipal wastewater treatment facility are trending higher than what’s expected of the collections system, I&I are the likely culprits. However, because issues like manhole leaking, inflow and infiltration are worse within cracked or deteriorating sewer structures, you should consider I&I symptoms of larger structural deficiencies in your sewer system. Aging structures and ill-maintained collections systems provide easy access for clear water to enter the manhole and place further strain on the system. So the sooner you can get ahead of these problems, the better. To help prevent I&I, it is vital to schedule regular manhole inspections to evaluate drainage and identify joint leaks that may be contributing to the problem.

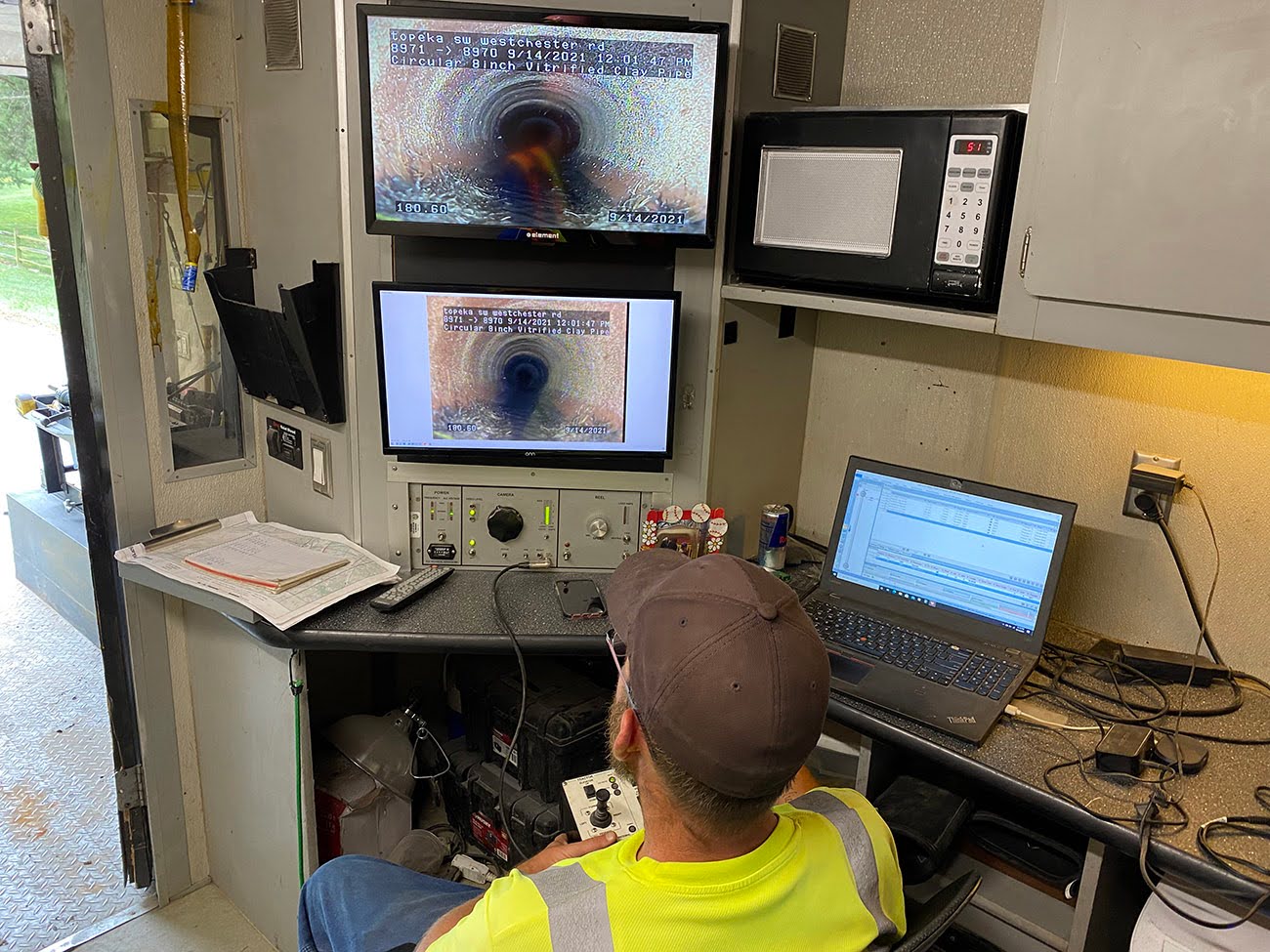

At HK Solutions Group, we support municipalities with a sanitary sewer maintenance program including a full range of inspection services, like proactive annual CCTV and 3D manhole inspections. Cutting edge inspection technology identifies deficiencies as small as 1 mm in size, and our MACP-certified technicians use this data to compile all defects identified by type and severity.

Another more localized option to find inflow and infiltration in the sewer system is smoke testing. Smoke testing is an efficient and cost-effective way to find and identify cracks and leaks causing infiltration problems in sewer systems. The process involves blowing air and smoke into the sanitary sewer system. Regardless of the depth, the smoke will fill up and eventually rise to the ground, identifying the location of a pipeline leak. While smoke testing does a good job of pinpointing where cracks or other deficiencies are located in a pipeline, regular manhole inspections are still a good idea to get a comprehensive understanding of sewer system conditions and facilitate long-term planning for early issues.

Either way, once inflow and infiltration are identified, mitigation and reduction techniques like manhole rehabilitation are critical next steps to reduce the effects on the sanitary sewer system.

How Manhole Rehabilitation Reduces Inflow & Groundwater Infiltration In Sewer Systems

When it comes to storm and groundwater infiltration in sewer systems, the most effective strategies to reduce I&I include proactive maintenance of the sanitary sewer system and acting quickly when issues are discovered. Trenchless manhole rehabilitation solutions provide long-term structural stability for sewer infrastructure without the time- and cost-prohibitive hassle of excavation. By working with experienced manhole inspection and rehabilitation technicians, you can make informed decisions about how to best resolve manhole leaking, inflow and infiltration.

Professionals have the ability to analyze output from a manhole inspection to determine deficiencies in the system and recommend the most cost-effective rehabilitation solution. For systems that need manhole repairs but not a complete structural restoration, effective techniques to mitigate I&I include:

- Mainline pipe joint and lateral connection grouting

- Manhole barrel joint and pipe connection grouting

- Manhole chimney seal installations

- Replacement of worn castings and covers with new units that have gasketed lids

These minimally invasive solutions seal the existing manhole and sewer structures so that groundwater and stormwater cannot make their way into the collections system. However, more severe structural defects call for a fully structural solution, while still limiting disruption to your community. That’s where manhole lining with innovative solutions like Monoform PLUS™ comes in.

Monoform PLUS™ For Manhole Leaking & Other I&I Issues

Monoform PLUS™ is a 100% structural and 100% corrosion-resistant manhole rehabilitation solution able to restore an existing manhole from within, using an ABS plastic forming system and ready-mixed concrete with an HDPE 100% corrosion resistant liner. The Monoform PLUS™ manhole rehab solution addresses high levels of H2S and associated corrosion to not only mitigate I&I long-term but also prevent future deterioration due to corrosive chemicals. This solution is fully structural and offers the same performance specs as replacing the manhole entirely, but at a cost savings and without the disruptions of rerouting traffic or turning off utilities. Our team at HK Solutions Group performs manhole rehabilitation using Monoform PLUS™ with confidence knowing we’re providing clients with a trusted solution. More benefits of this manhole lining technology include:

- Limited traffic and community disruptions

- Projects are typically completed within a few working days

- Fraction of replacement cost

- Engineered design life equal to replacement

- No backfill compaction issues like those that can occur when replacing a manhole via excavation

- External sewer bypass pumping is not required

Contact HK For Lasting Inflow & Infiltration Relief Through Manhole Rehabilitation

If leaking manholes, inflow and infiltration are impacting your ability to efficiently and effectively manage the sanitary sewer system and serve your community, trust HK Solutions Group for proactive, innovative manhole rehabilitation solutions. Our expertise and innovation allow us to tackle the toughest jobs and reduce the burden on sewer infrastructure and your team. Contact us to learn more about our manhole rehabilitation services and lining solutions to see how we can help you fight against inflow and infiltration in your collections systems.

Get Started With HK

Matt Huston

Matt’s expansive career spans 30 years working with trenchless, structural manhole rehabilitation technology to provide no-dig sewer solutions for industrial and municipal customers throughout the Midwest.

Over the years, Matt has been heavily involved with the Wisconsin Rural Water Association and Wisconsin Wastewater Operators’ Association, working his way through numerous committee positions to provide leadership to peers in the industry. He has also hosted impactful presentations for the associations outlining sewer system maintenance and structural manhole rehabilitation techniques.

Learn More About Matt