What Is Manhole Rehabilitation? Benefits, Methods & Uses Explained

November 6, 2025

Manholes are essential for maintaining critical underground infrastructure within an industrial facility or municipal sewer system. So shouldn’t manhole maintenance be a priority in its own right? Too often, manholes become the most neglected part of a sewer system, which leads to the deterioration of critical process pipes, wastewater disposal and even the ground you stand on. Instead of strengthening infrastructure, ill-maintained manholes become a liability, leaving your business or even the community at large in a precarious position.

To combat the inevitability of aging infrastructure, trenchless manhole rehabilitation techniques like manhole lining are innovative, cost-effective and efficient solutions to maintain sewer infrastructure without interrupting ongoing operations. Read up on everything you need to know about manhole rehabilitation and its many benefits for industrial and municipal sanitary, wastewater collection and process systems.

What Is Manhole Rehabilitation?

Manhole rehabilitation is the process of reinforcing and restoring a deteriorating manhole to avoid the financial strain and disruption of a full replacement. Manholes often endure years of wear and tear and exposure to highly corrosive elements, making them susceptible to inflow and infiltration issues. Inflow and infiltration stem from excess ground or stormwater seeping through cracks or holes in the manhole structure, reducing operational capacity and creating inefficiencies that contribute to higher costs. The most cost-effective approach for manhole maintenance, trenchless rehabilitation solutions like manhole lining restore existing manholes to like-new condition, avoiding the need for a cost-prohibitive replacement. Manhole rehab revitalizes existing sewer structures without disrupting municipal road traffic or digging up facility floors in independently operated industrial facilities.

Is Manhole Rehab Only For Municipalities?

Manhole rehab is a smart solution for municipal maintenance, but it also resolves many of the challenges facing independent facilities maintaining their own sewer infrastructure. Much like municipal manholes, manholes in industrial facilities are vulnerable not only to inflow and infiltration, but also corrosive conditions. Facilities that work with chemicals and other harsh substances can benefit even more from manhole maintenance as chemical runoff rich with hydrogen sulfide (H2S) weakens the manhole structure.

Instead of uprooting business and disturbing day-to-day operations with an expensive excavation and full manhole replacement, trenchless sewer rehabilitation methods are well-suited for facilities to minimize expenses while maximizing efficiency.

Why Manhole Maintenance Matters For Municipalities & Industrial Facilities

Manhole maintenance is imperative for a sewer structure’s integrity, whether it’s preventing hazardous floods and overflow in city streets or safely disposing of chemical runoff in industrial facilities. Both public and private sewer infrastructure pose major health and safety risks to the surrounding community and environment if systems fail. Timely inspections and trenchless repairs catch damage early before it escalates into a major health hazard or operational shutdown. Without routine maintenance and proactive rehabilitation, your underground infrastructure has the unpredictability of a landmine, and you’ll be left to pick up the pieces.

How Do You Fix A Manhole?

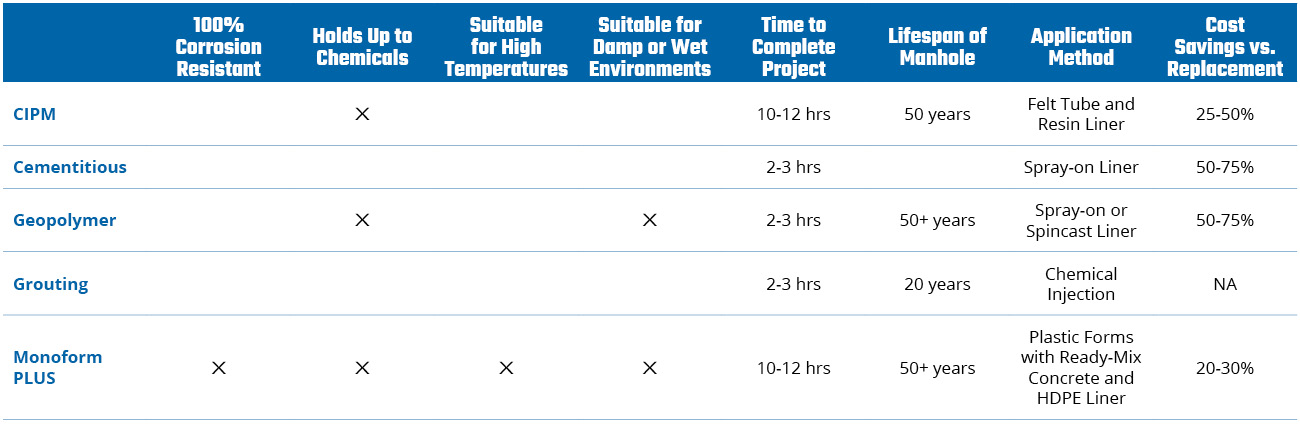

Deteriorating manholes require professional manhole rehab with experienced technicians who specialize in sewer structure repair. The right trenchless sewer rehabilitation partner should have a variety of manhole lining and grouting solutions at their disposal. Each has its own purpose depending on the status of your infrastructure, and all introduce cost savings and/or convenience compared to a replacement.

Types Of Manhole Rehab

The right trenchless rehabilitation solution will not only restore ailing structures but also enhance durability and promote longevity against harsh environmental conditions. Whether your underground infrastructure is up against high temperatures, corrosive chemical conditions or damp environments, there’s no match manhole rehab can’t tackle.

Cured In Place Manhole (CIPM)

A cured in place manhole (CIPM) liner is a felt tube that relies on resin in its core to tightly secure the manhole as the tube is inflated and the catalyzed resin hardens. CIPM works well for traditional cylindrical manholes but typically requires larger crews and more equipment to get the job done than other trenchless rehabilitation methods.

Geopolymer Manhole Linings

Geopolymer linings are cement-based and act as a glue, coating the manhole and forming a seal to support the structure. HK Solutions Group is an industry leader in the application of geopolymer linings designed to combat corrosion. Geopolymer linings are effective in corrosive environments and provide a structural enhancement to the host structure.

Cementitious Liners

Cementitious liners are a relatively low-cost and easy-to-apply solution. Typically cementitious manhole linings are applied during a low-pressure spraying process. They aren’t ideal for corrosive environments, but recent improvements have led to better protection against infiltration, lengthening the manhole’s lifespan.

Manhole Grouting With Chemical Injections

Manhole grouting is a good option for cracked or leaking structures and involves applying gel within the manhole to seal and waterproof the cracks and/or construction joints and seams to effectively prevent inflow and infiltration. Grouting is preferred for sealing manhole structures subject to leaking but is not recommended for infrastructure that is structurally failing, as a more comprehensive approach is required for advanced deterioration.

Monoform PLUSTM Manhole Lining Solutions

While there are many benefits and applications for other manhole lining solutions across the spectrum of trenchless sewer rehabilitation methods, some projects require outside-the-box thinking. That’s why our team at HK Solutions Group developed Monoform PLUS™, combining our fully structural Monoform™ solution with a high-density polyethylene (HDPE) Agru corrosion protection barrier. These two technologies provide a 100% structural and 100% corrosion resistant remedy, the only of its kind, for corrosive geographies or facilities working frequently with chemicals. HDPE manhole liners are durable and last longer than traditional manhole structures that deteriorate rapidly from high H2S concentrations.

Benefits Of Trenchless Manhole Rehabilitation Vs. Replacement

Whether sewer structures are located in a strenuous environment (such as areas of extreme heat or highly corrosive areas) or have simply deteriorated over time, industrial facilities and municipalities alike can trust trenchless manhole rehabilitation methods to restore the integrity of their infrastructure. Many manhole lining solutions have the equivalent lifespan of a full manhole replacement without the unnecessary expense and interruption to your day-to-day operations. And this is just one of many reasons why manhole rehab makes more business sense than manhole replacement.

Manhole Rehab Is Cost Effective

Trenchless rehabilitation increases cost savings because you avoid the initial digging and the extra expense of having to rebuild afterward. Saving in both regards is one of the key reasons why rehabilitation is a preferred solution for manhole maintenance.

Manhole Rehab Leads To Less (Or No) Downtime

Trenchless sewer rehabilitation allows municipalities and facilities to stay fully focused on business matters because there is no need to shut down operations to accommodate large construction equipment and gaping holes. With no digging involved, rehabilitation crews are typically able to complete projects within 10 to 12 hours, without interrupting daily operations.

Some Trenchless Solutions Have A Lifespan Equivalent To Full Replacement

There are many types of trenchless rehabilitation methods with varying lifespans. For the best outcome, look for a solution that is fully structural and has a lifespan in line with replacement (about 50 years). With less hassle and a lower expense to implement, it makes more sense to rely on manhole rehabilitation for lasting longevity. If you’re struggling to maintain sewer infrastructure or are increasingly fed up with failing manholes, HK Solutions Group specializes in innovative trenchless sewer rehabilitation services across the U.S. with manhole lining solutions tailored to best address your needs.

Contact HK For Trenchless Sewer Rehabilitation & Manhole Lining Services

At HK Solutions Group, our approach to manhole maintenance is designed for your convenience to keep your city or facility functioning properly. To learn more about our talented team of manhole rehab experts and top-of-the-line manhole lining solutions, including our 100% corrosion-resistant Monoform PLUS™, contact us to get started.

Get Started With HK

Matt Huston

Matt’s expansive career spans 30 years working with trenchless, structural manhole rehabilitation technology to provide no-dig sewer solutions for industrial and municipal customers throughout the Midwest.

Over the years, Matt has been heavily involved with the Wisconsin Rural Water Association and Wisconsin Wastewater Operators’ Association, working his way through numerous committee positions to provide leadership to peers in the industry. He has also hosted impactful presentations for the associations outlining sewer system maintenance and structural manhole rehabilitation techniques.

Learn More About Matt